It is Autumn here in Western New York, maple trees are in full color of brilliant hues of red and burnt orange.

The

temperatures and cooling down and the wildlife around the farm are getting

ready for the harsh winter months ahead.

Autumn also is the time when our festival season peaks in a grand finale for the year - the largest fiber festival in the country, the New York State Sheep and Wool Festival.

Important Festival Details

The festival is

commonly referred to as Rhinebeck, because it is located in the village of

Rhinebeck. But technically it is the New

York State Sheep and Wool Festival

It takes place

at the Dutchess County Fairgrounds which is situated in the Catskill mountains,

close to the hudson river, about 100 miles north of New York City.

Our History Vending at the Rhinebeck Fiber Festival

We have had a

vendor booth at this festival for 4 years, starting in 2019. I was still working full time for a company

in addition to having the farm compared to now where I am a full time farmer. Also, I only had the Rose for demo spinning,

and I still had a lot of raw fleeces on offer where now they sell in the spring

during my annual fleece auction.

In 2020 the festival went virtual due to Covid 19, so I just set up my booth in the garage and sat in front of my phone in a day long zoom session. We didn’t have high speed internet at the time, so I was relying on my cellular service in order to serve the customers that stopped into my “shop” the 4 days of the event. I had a lot more Majacraft supplies, and the sheep heid kits which I don’t make any more, and I had a small amount of roving, I hadn’t started offering combed top yet.

In 2021 they controlled ticket sales to 20,000 and spaced the vendors out, and were monitoring the direction of lanes inside the buildings to prevent face to face contact. I remember how happy I was to be back talking to all my fibery friends, and because of controlled ticket sales I was able to spend time with people that were interested in learning more about the craft of handspinning. My niece Gigi came along to help that year. And this year I had the full lineup of demo equipment and combed top was now the mill prep. And this was the year I realized I had outgrown our minivan and would need to consider renting a larger vehicle!

2022 was busy, we had a lot of people browsing and enjoying the wheels, and I

was still able to spend one on one time with people which is really important

to me. This year, 2023, we were slammed,

to the point where I was taking care of three customers at once for practically

the entire day on Saturday.

Products Featured in our Booth

We raise shetland sheep with the singular purpose of producing wool that is ideal for handspinning. I am also an authorized Majacraft dealer, and I hold stock of al the wheels, fiber preparation tools and accessories.

Our fiber

festival booth always has Majacraft demo wheels for people to try, all the

fiber preparation tools to play with and then wool from our sheep in various

forms. I try to offer wool products that

satisfy the diverse range of fiber crafting possibilities.

So I offer hand

processed bats that I hand washed, flicked and then drum carded into batts.

Hand processed

handspun yarn

Then I try to provide mill preparations of our wool, so I offer mill spun yarns

And combed top

in all 5 natural colors

These are the

staples, then I’ll sprinkle in other farm related things just based on what

materials I have available

Friday

Our drive to Rhinebeck is a 5 hour road trip.

The van is

packed the night before so that on friday morning all we need to do is take

care of the sheep and then hit the road

We made

arrangements to have our son take care of the sheep for the festival weekend

Only a few more

miles to the fairground once we pass this famous landmark - the festival

billboard

Saturday

We arrive at

the fairgrounds a few hours before the festival start time of 9 am. Once the booth is ready, we like to walk

around and check out other booths

Rich and I have

split the booth duties during fiber festivals. Rich is the one in charge of checking out

customers

I am

responsible for consulting with customers to find solutions to their making

needs- ,

helping them

understand the wool from our sheep in all its forms

The Fleece Show and Sale

We arrived

early enough on Sunday, before the festival began to be able to look at the remaining fleeces from the Fleece

show and sale - It is important for us as breeders to examine the wool being

produced by other farms to see what we can learn.

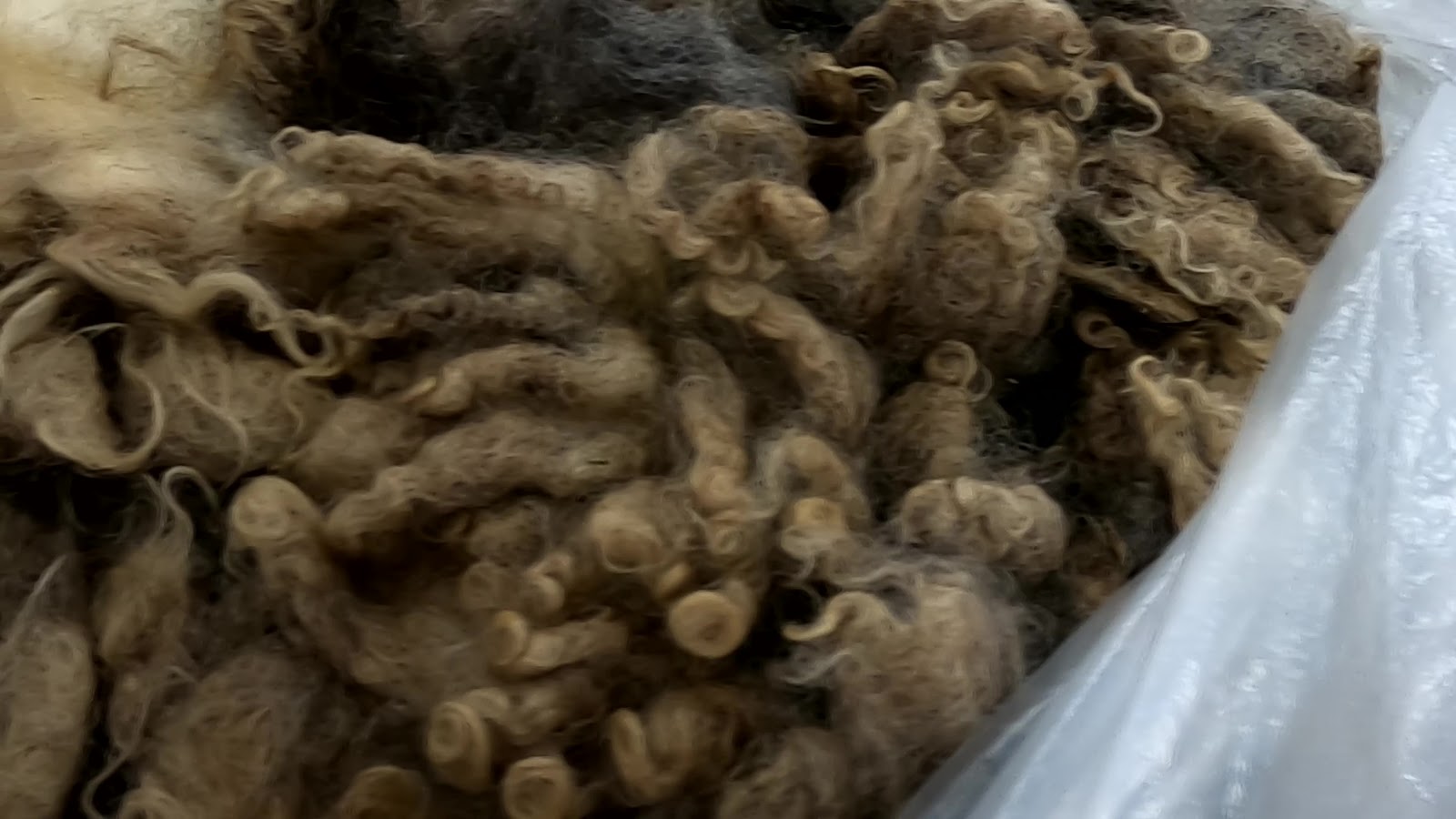

Shetland fleeces in the US don’t have a uniform type. Some are very long and straight, others are short with crimp. And then many fall in between. They are all considered acceptable by the breed association. I think this variation makes it difficult for a handspinner to source shetland fleeces - especially if they are looking for a specific type. You can see this variation here where these are all shetland fleeces but all look very different.

We like to

breed for very fine, crimpy fleeces that are dense and nice and soft, this one was the closest to what I like to work with.

The Sheep barn

We make it a

point to spend time in the sheep barn where you get to see a very nice variety

of fiber producing animals and speak to the farmers who raise them.

Souveniers

We preordered

festival souvenirs this year and picked them up when we arrived. If you want souvenirs from the festival it is

best to preorder. I put this link in the

description which you can follow to sign up for notifications when the

souvenirs become available next year. I

loved the artwork this year and because we preordered, I was fortunate to be

able to secure the very popular tote bag.

Every year the festival holds an art contest. Artists submit their designs for the next year’s festival artwork. Attendees to the festival can vote for their preferred design. The artist with the most votes has the honor of having their design used on all the merchandizing, web graphics and signage for the next year’s festival.

This years artwork was created by Jeanne Goodman -

and she is a professional artist with an impressive resume and works all over the country. I read that she primarily works in colored pencils and color pencil art sticks.

Never saw a sheep this color, but I’ve seen sheep that made me think about these colors - perhaps a Gotland or a Wensleydale

I keep on

running back thru my head the conversations and things I was told by people who

came into our booth and I have to say I am so grateful for everyones' support

and kind feedback about our farm, our YouTube channel and the products we are

trying to supply to this lovely community of fiber crafters. Thank you so much to all who stopped by, and

those of my “locals” who saw how crammed we were and just gave me a friendly

wave or quick hug as they were swept by in the traffic flow.